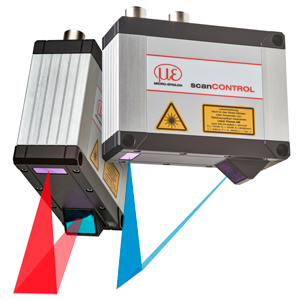

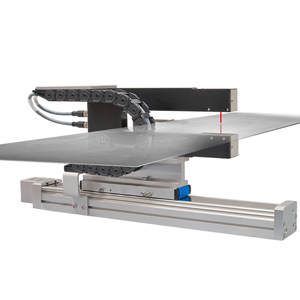

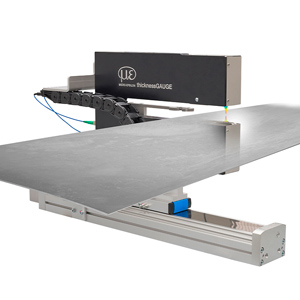

Precise dimensional inspection even with strong vibrations

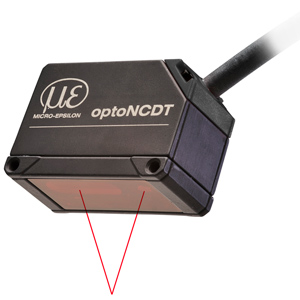

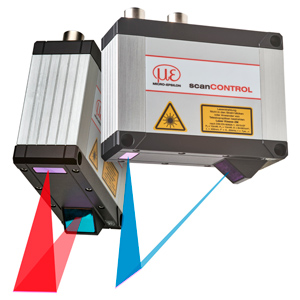

Vibrating targets pose a particular challenge in optical measurement technology: Due to the constant movement, the position of the target changes during detection, which can cause unclear or incorrect results. The laser can be blurred by the movement or deflected from the target, causing the return signal to be less precise or to fail completely.

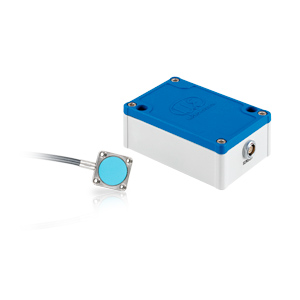

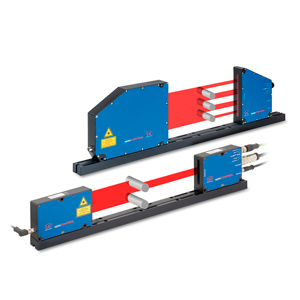

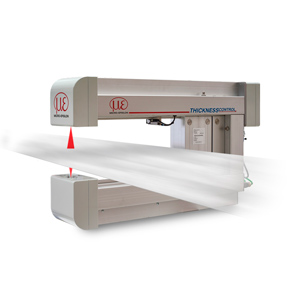

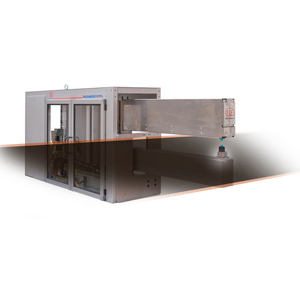

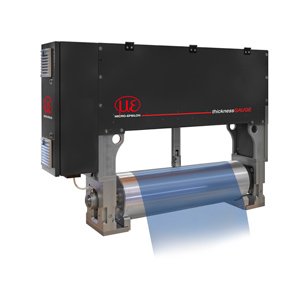

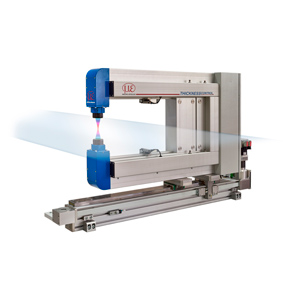

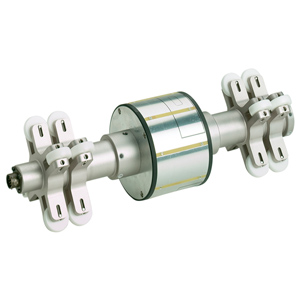

The optical precision micrometers of the optoCONTROL 2700 series from Micro-Epsilon are specially designed for such dynamic measurement tasks. With a sampling rate of 15 kHz and an extremely short exposure time of just 8.5 µs, they detect even vibrating or fast-moving objects reliably and with high accuracy.

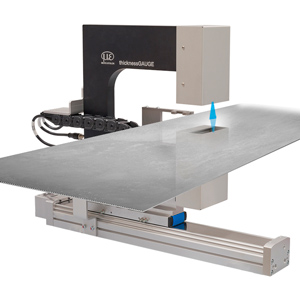

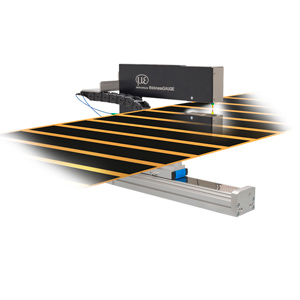

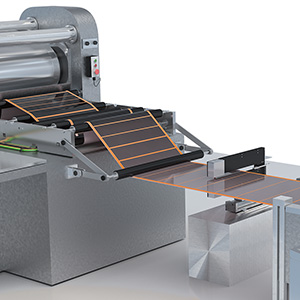

Real-time inclination correction

The receiver's image matrix captures the exact alignment and therefore the angle of the object in the light beam via the primary line and secondary line. The internal controller automatically adjusts the measured value to the inclination of the target. As a result, the exact measured value is output and no measurement errors occur. The inclination correction applies over the entire measuring rate and can be used in the measuring programs for outer diameter, web edge and contour measurement.

With the optoCONTROL 2700, typical measured variables such as diameter, gap width, edge position or segment length can be precisely determined even at high production speeds, for example in inline quality assurance or machine monitoring. The system is available in measuring ranges of 10 mm and 40 mm. A particular highlight is the controller integrated in the receiver, which reduces the cabling and installation effort as no external control unit is required. The precision micrometer outputs the measured values via the integrated web interface and the digital interfaces.