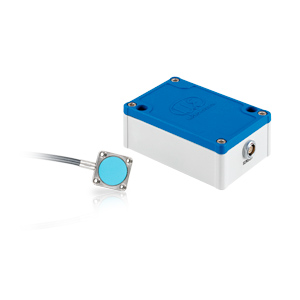

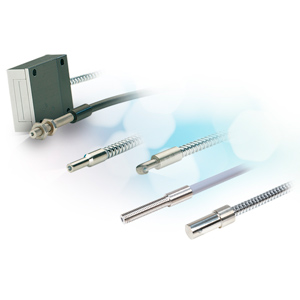

Capacitive high temperature sensors up to 800 °C

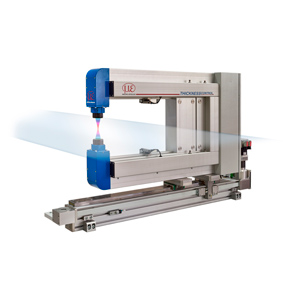

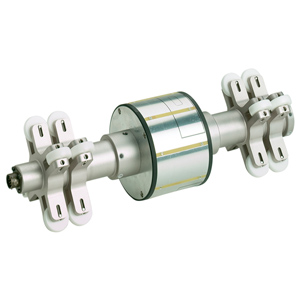

The new capacitive sensor system capaNCDT 6228 is designed for measurement tasks with ambient temperatures up to +800 °C. Up to four high-temperature sensors of the CSE/HT series can be connected simultaneously to the powerful controller. The integrated high-temperature sensor cable compensates for interference from electric or magnetic fields. Furthermore, the measured data is output both analog and digital via modern interfaces such as Ethernet and EtherCAT.

Podrobnosti

- Precise distance measurement at extreme ambient temperatures from -50 °C to 800 °C

- Resolution from 10 nm

- Frequency response 1 kHz (-3 dB)

- Analog output 0 ... 10 V / 4 ... 20 mA

- Digital interface: Ethernet (with controller DT6228) / Ethernet and EtherCAT (with controller DT6238)

- Up to 4 measuring channels per controller

- Synchronization of more than 4 measuring channels with controller DT6238

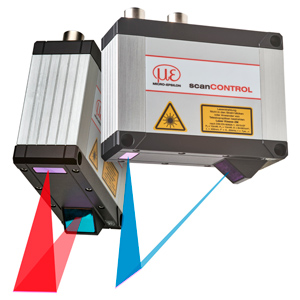

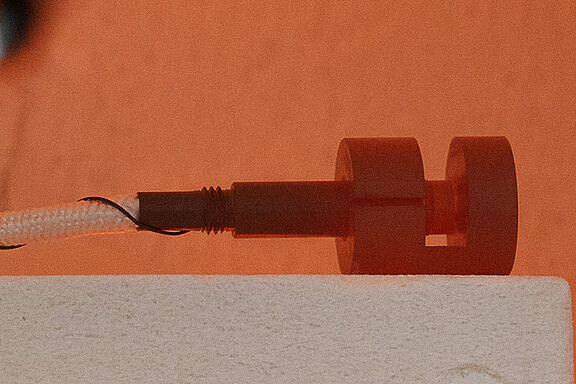

Highest precision at extreme temperatures

The capaNCDT CSE/HT high temperature sensors are used for measurements at ambient temperatures from -50 °C up to +800 °C. Thanks to its high temperature stability and exceptionally high linearity, the measuring system provides precise results even in challenging ambient conditions. In addition, the available sensors cover measuring ranges from 1 mm to 20 mm.

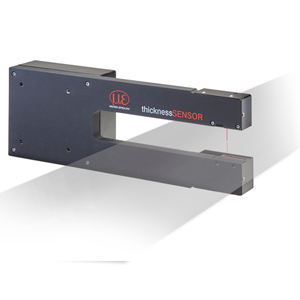

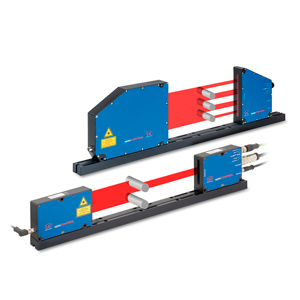

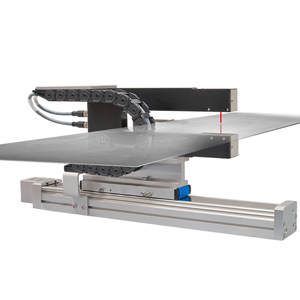

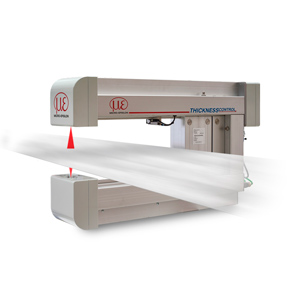

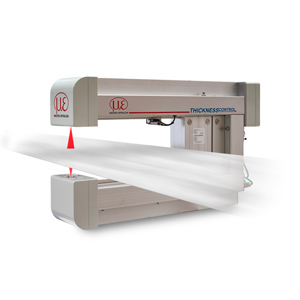

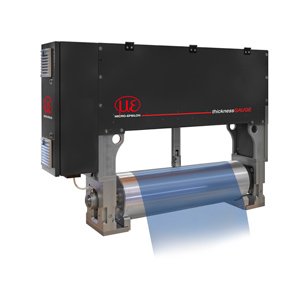

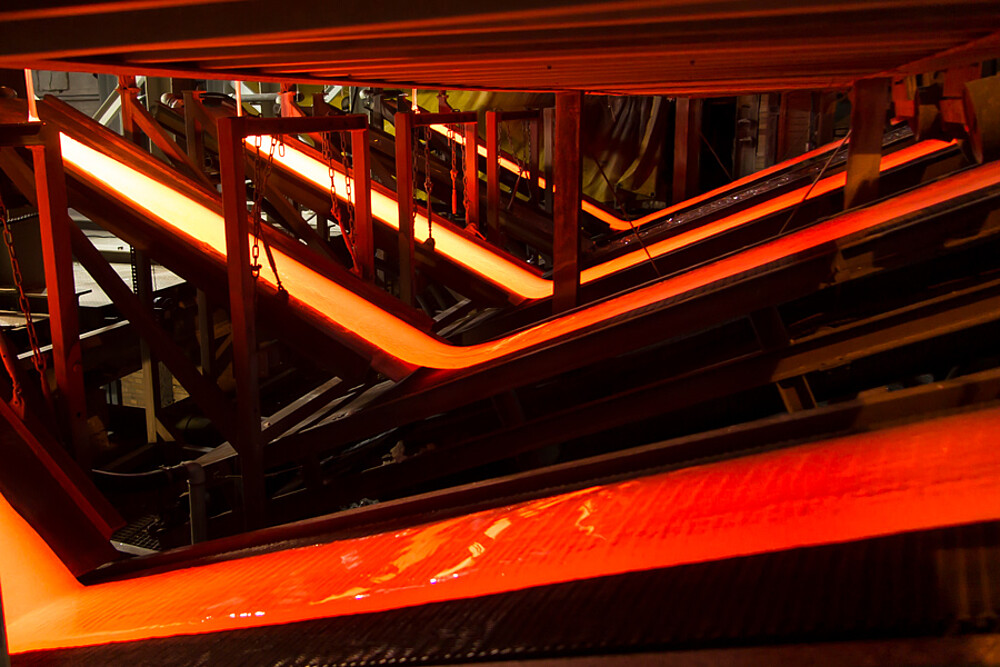

Ideal for distance and thickness measurements at high ambient temperatures

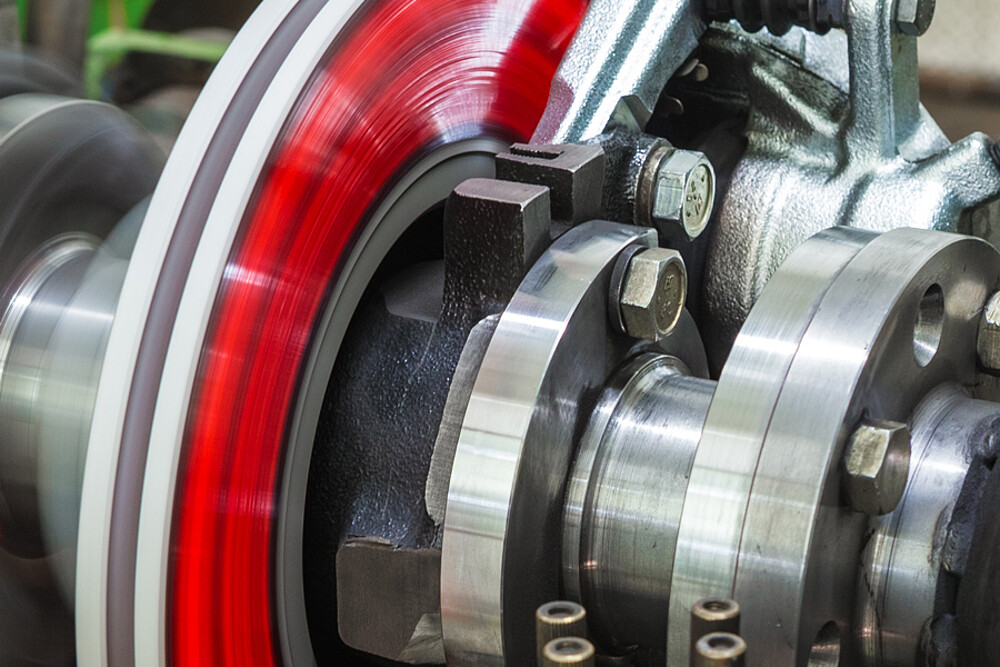

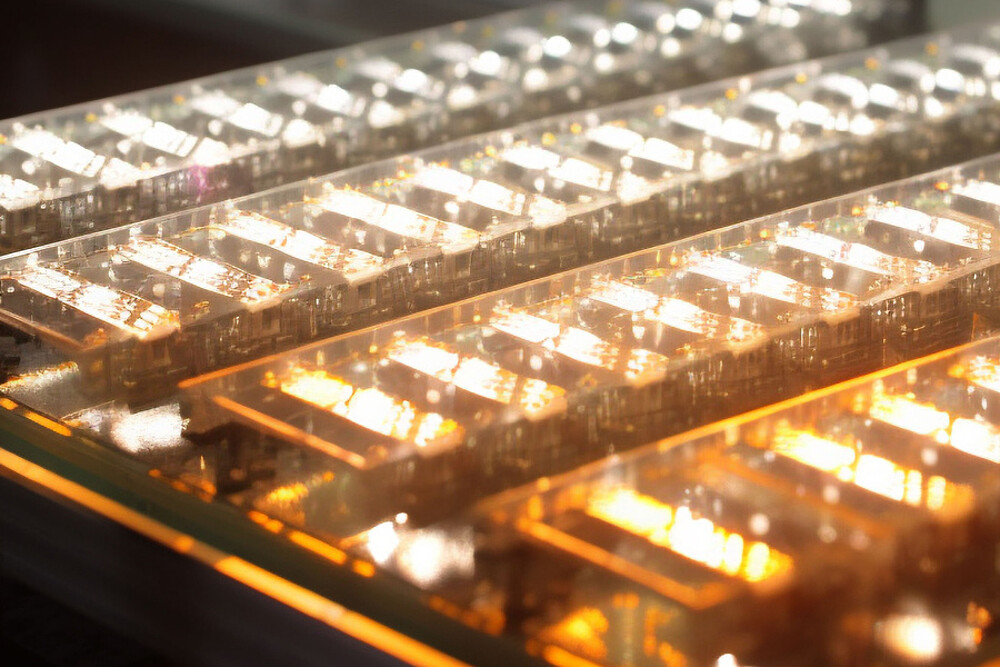

The capaNCDT 6228 is used, among other things, to measure the thickness of glowing brake discs from two sides and to monitor the level of float glass. In addition, the extremely good temperature stability enables high measurement accuracy.

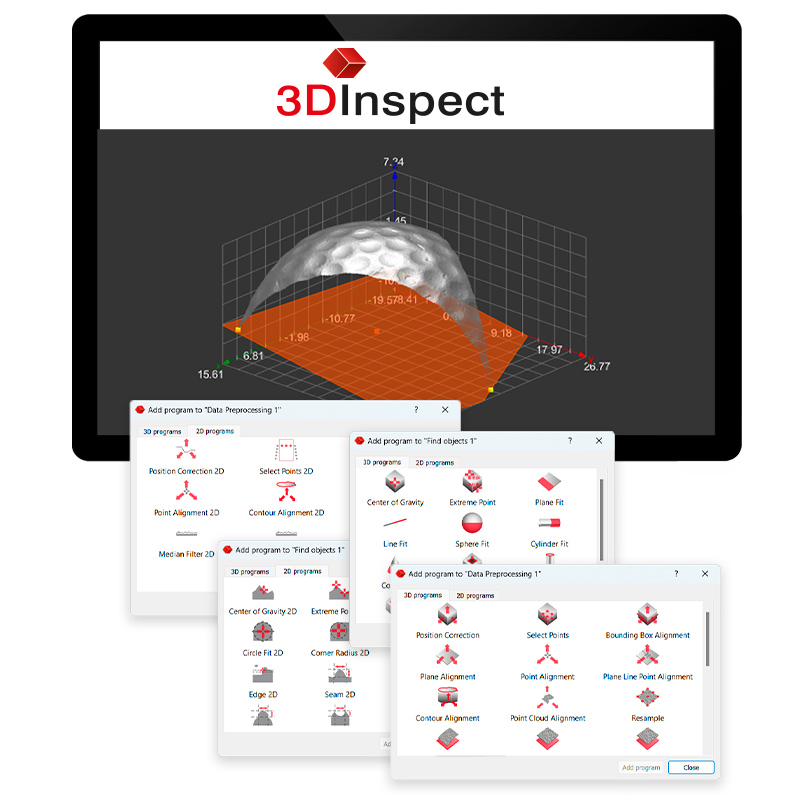

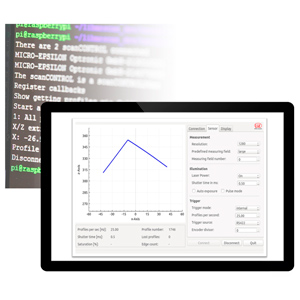

Jednoduchá ovladatelnost pomocí webového rozhraní

Z důvodu uživatelského webového rozhraní se provádí celý proces konfigurace kontroléru a snímače bez použití jakéhokoliv dalšího softwaru. Webové rozhraní může být přístupné přes Ethernet a poskytuje nastavení a konfiguraci filtrů, aritmetických operací a ostatních parametrů.