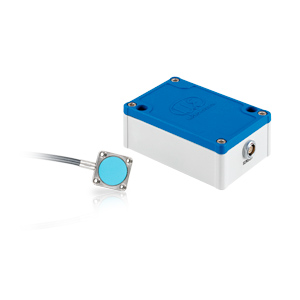

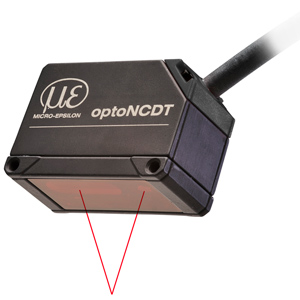

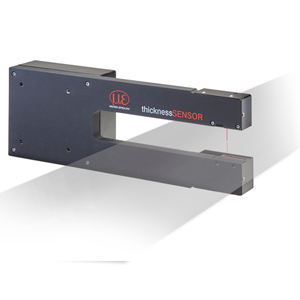

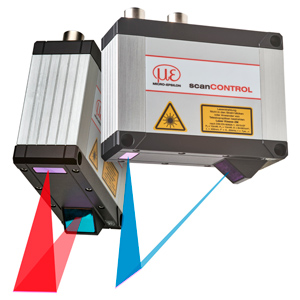

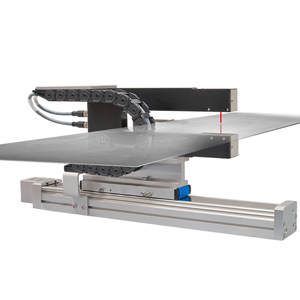

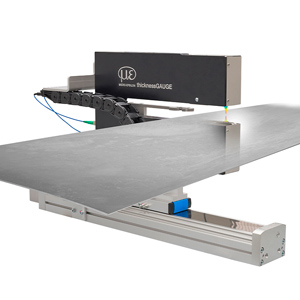

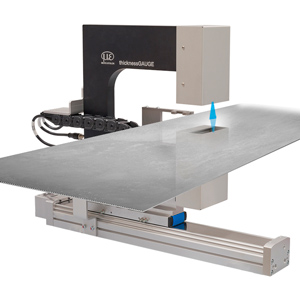

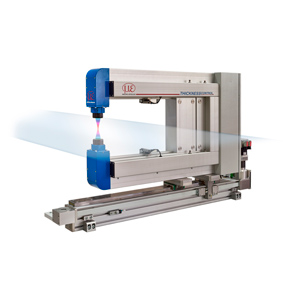

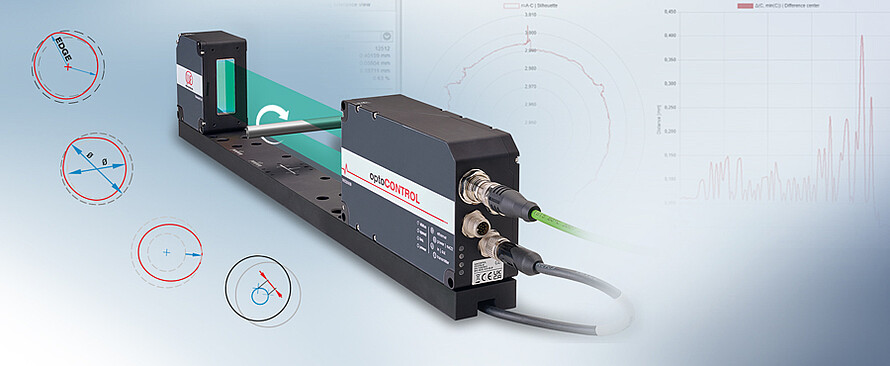

With the firmware update V012.000, the optoCONTROL 2700 now offers the option of a full 360° inspection of rotating components. Instead of only detecting a measurement value at a single point, the target is rotated and evaluated over its entire circumference. The system detects various shape and positional tolerances such as runout, roundness, concentricity and ovality. The results are clearly displayed in a pie chart and can be called up directly via the sensor's web interface.

Shape and positional tolerances

The runout is the measure of how much a rotating target deviates from its ideal axis of rotation. It is given by the difference between the maximum and minimum distance of the circumference from the reference point and provides general indications of deviations from a circular shape. Roundness describes how much the cross-section of a round target deviates from an ideal circle. The concentricity is given by the difference between the maximum and minimum center axis of the object. It indicates how far the axis deviates from the optimum center axis. Ovality is a special shape deviation in which the cross-section is not circular but elliptical. It is defined by the difference between the maximum and minimum outer diameter in relation to the mean outer diameter.

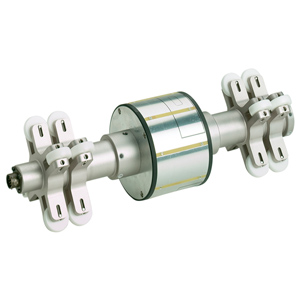

Extended range of possible applications

The new features of the sensor can be utilized in the production of mechanical shafts or rotating components, among other things. Here, it is particularly crucial to detect shape deviations in order to ensure correct functioning, fitting and mobility. In the glass industry, the sensor provides rotationally symmetrical evaluation of clear glass tubes, as the optical precision micrometer also measures transparent materials with high precision.