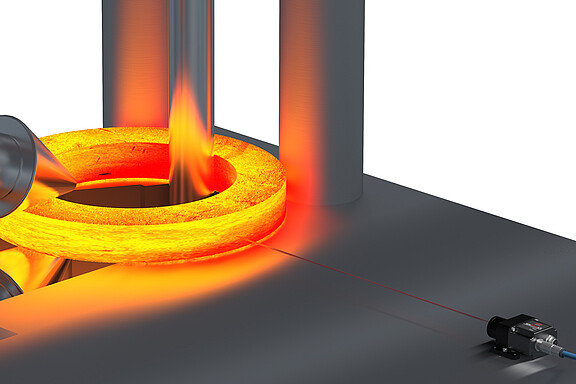

Diameter monitoring on seamless rolled rings

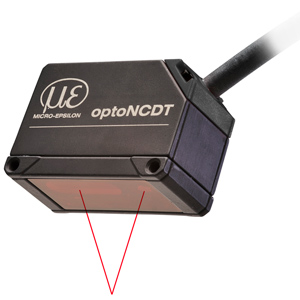

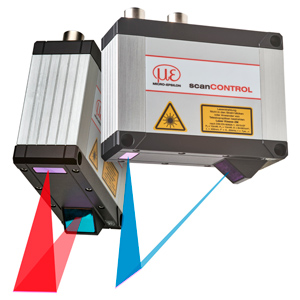

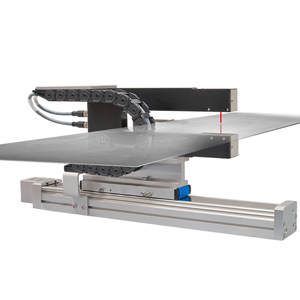

optoNCDT ILR2250-100 laser distance sensors from Micro-Epsilon are used for this measurement task. They operate on the phase comparison method, which provides reliable results even on red-hot glowing measuring objects. The sensor is mounted at a safe distance from 1 m to 10 m and precisely measures the distance to the rolled material during rolling. During the production process, the diameter of the ring constantly increases, which reduces the distance from the sensor. The sensor detects this difference reliably and to millimeter accuracy. The generated measurement values are transmitted directly to the production control system via the digital interface. Now the diameter can be calculated as well as the remaining rolling path, which is comprised of the actual volume and the resulting actual dimensions. The results are then transmitted to the control room for visualization.