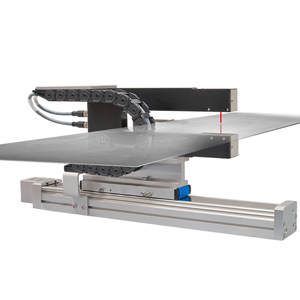

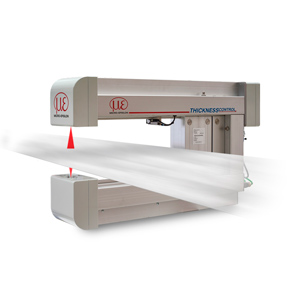

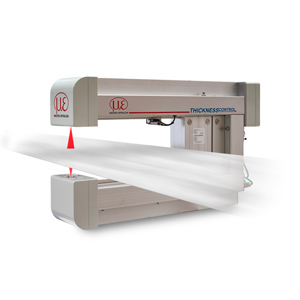

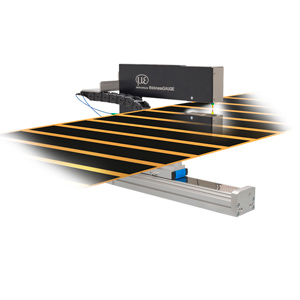

Profile measurement and distance control during forging of wheel tires

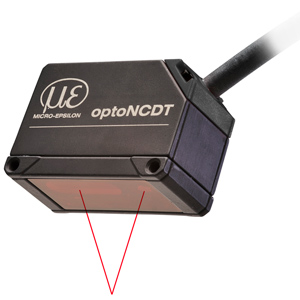

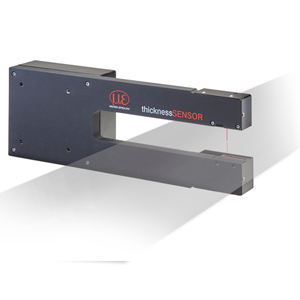

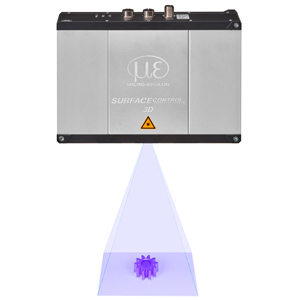

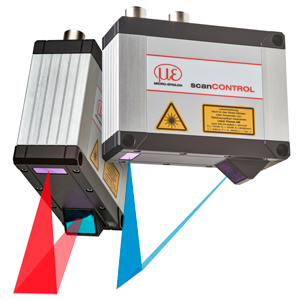

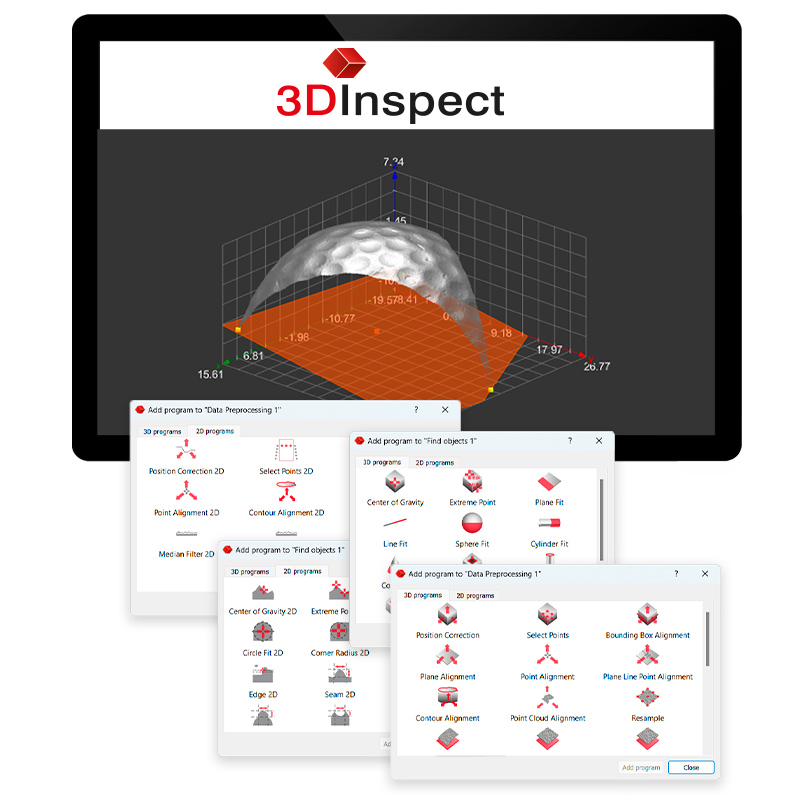

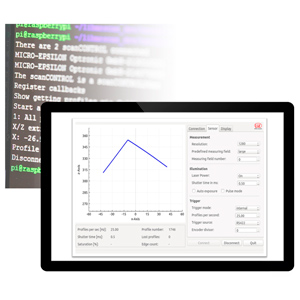

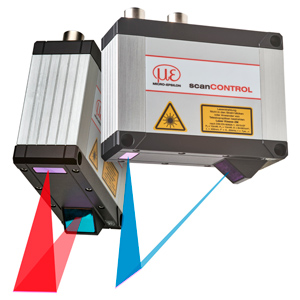

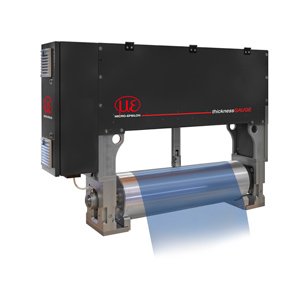

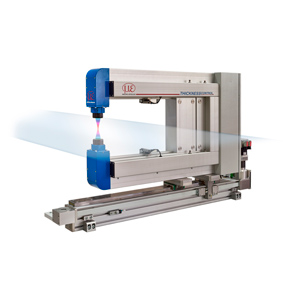

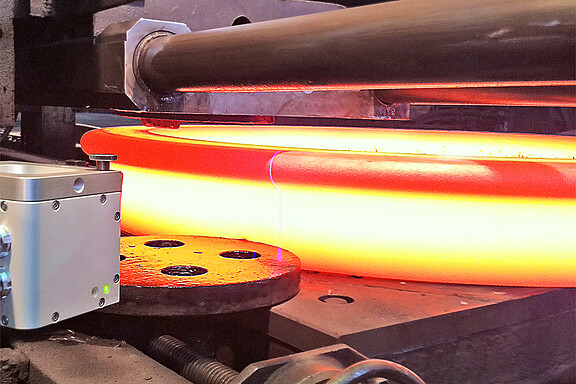

Blue laser scanners from Micro-Epsilon are used to monitor the dimensional accuracy of wheel tires during forging. Conventional laser scanners reach their limits with red-hot glowing steel, as its radiation intensity is too high for the sensor element. The Blue Laser Technology from Micro-Epsilon is patented for measurement tasks with glowing steel. This allows the wheel tire profile to be continuously monitored during forging in order to feed the measurement data to the control system.

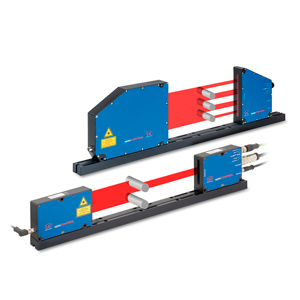

Laser time-of-flight sensors are used to monitor the position of the glowing blank. These measure the position from a safe distance and thus enable safe handling of the gripper.