Precise sensor solutions for battery production

Micro-Epsilon offers high-precision sensors and measuring systems for the production of electrode film, coatings and battery cells. Our solutions enable maximum measurement accuracy – from the thickness measurement of battery film to the sophisticated 3D inspection of coated materials. Even at high temperatures and process speeds, our sensors deliver reliable results and ensure stable coating processes. This is why leading battery manufacturers and automotive groups worldwide rely on Micro-Epsilon – sensors for battery production with more precision.

Why choose Micro-Epsilon?

Highest product quality: Precise inline thickness measurement, coating control and 3D inspection

Minimize waste and downtime: Long-term stable, temperature-independent sensor technology

Increase process efficiency: Advanced sensors and measuring systems from a single source

Short way to series production: Close OEM partnerships and technological expertise

Innovative edge for our customers: Made in Germany with in-depth application knowledge for battery production

More precision for battery production

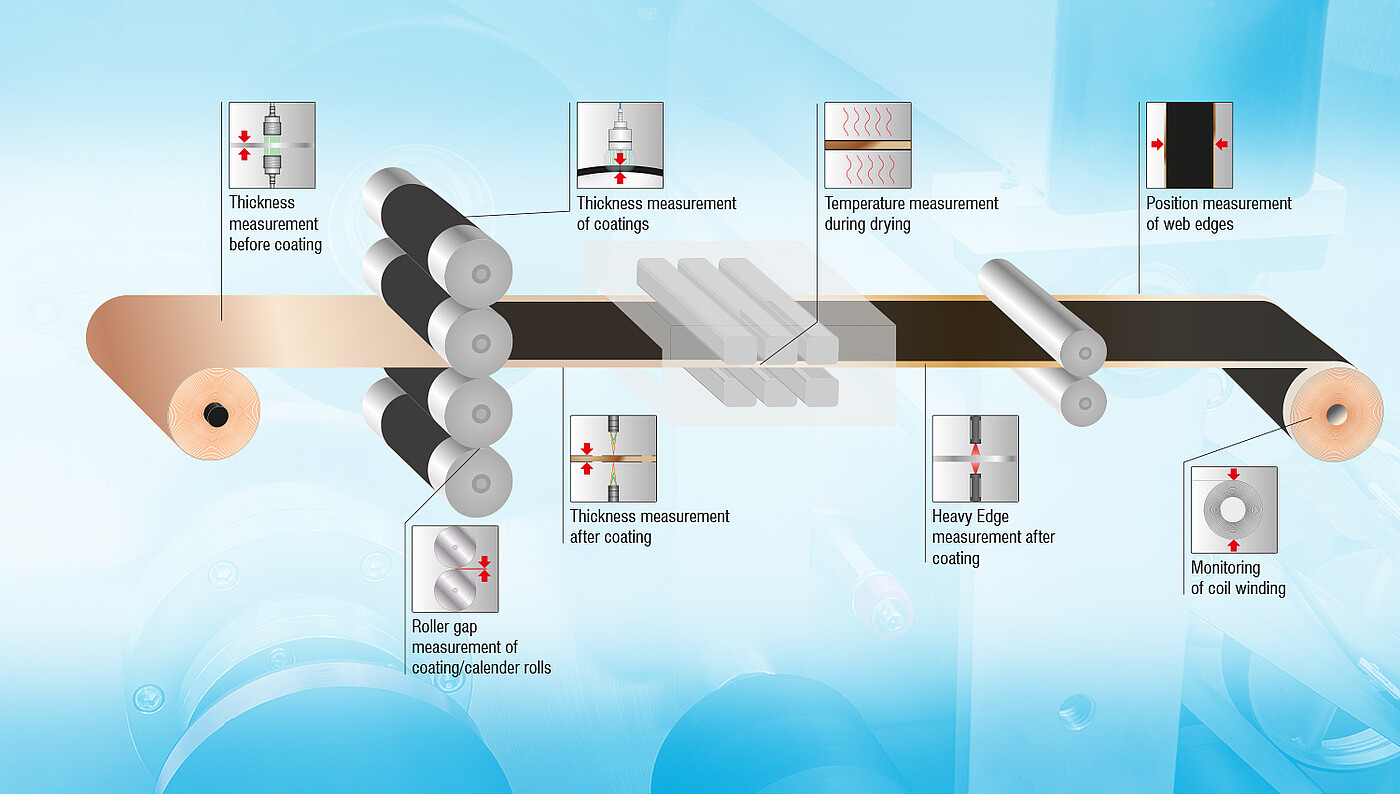

Micro-Epsilon offers the right solution for diverse battery production applications – from inline thickness measurement to precise machine monitoring and 3D surface inspection. The sensors are used by leading battery manufacturers and automotive companies around the world and impress due to their supreme precision and reliability.

Application examples from the battery industry can be found here

Highly precise sensors for measuring the thickness of battery films

Non-contact displacement sensors from Micro-Epsilon offer numerous advantages in thickness measurement. Capacitive sensors, for example, have a relatively large measurement spot that compensates for inhomogeneous structures. Furthermore, capacitive sensors can be used at high temperatures. Thanks to integrated temperature compensation, the sensors deliver stable measurements in the submicrometer range and can also be used in drying processes.

In the case of optical thickness measurement, confocal chromatic sensors really come into their own, as do white light interferometers for the inline thickness measurement of battery films. The sensors are typically used to monitor and control wet coating processes, but are also suitable for dry coating processes.

You can be sure of the best sensor for the measurement task at hand, no matter what measuring object or type of coating (uncoated/coated) is involved. Just get in touch!

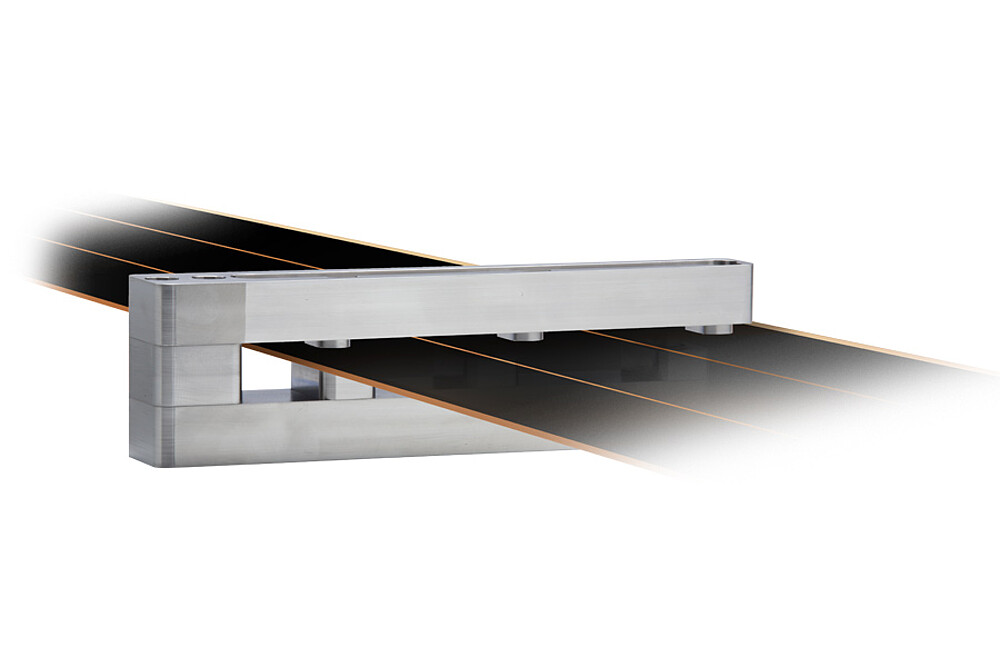

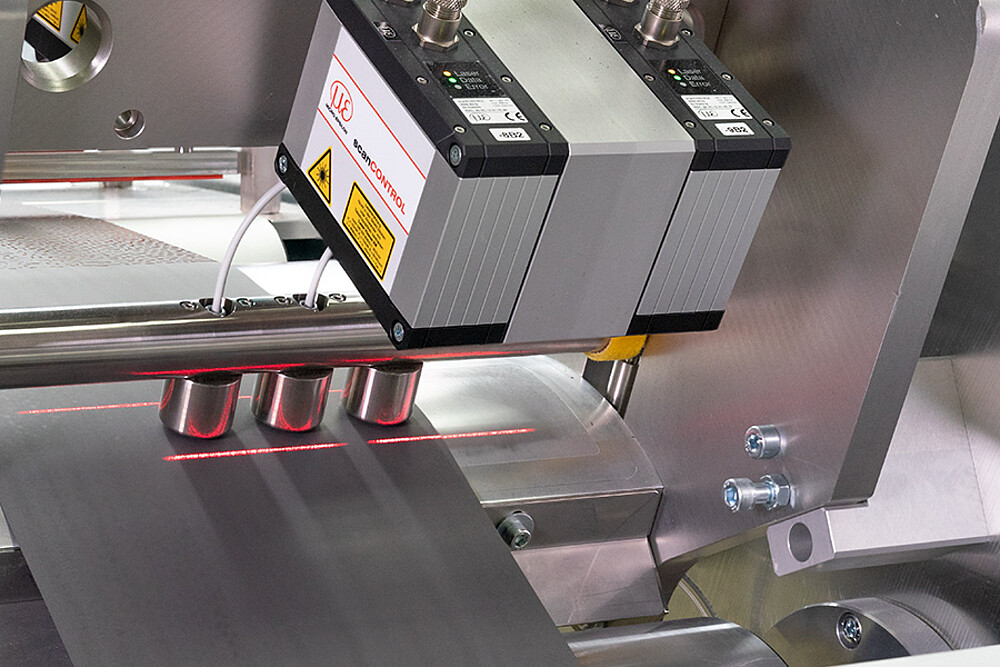

3D sensors and dimensional measurement technology for electrode and battery manufacture

3D sensors from Micro-Epsilon are used for assembly monitoring and for 3D inspection of coated films. 3D laser scanners are suitable for continuous strip inspection, while 3D snapshot sensors are used for stop-and-go measurements with exceptionally high precision. The 3D sensors by Micro-Epsilon allow for stable measurement with a high resolution and detect flaws on the smallest of shapes, such as spalling and inclusions. Optical micrometers that reliably check sheet travel are used to monitor the edges of strips.

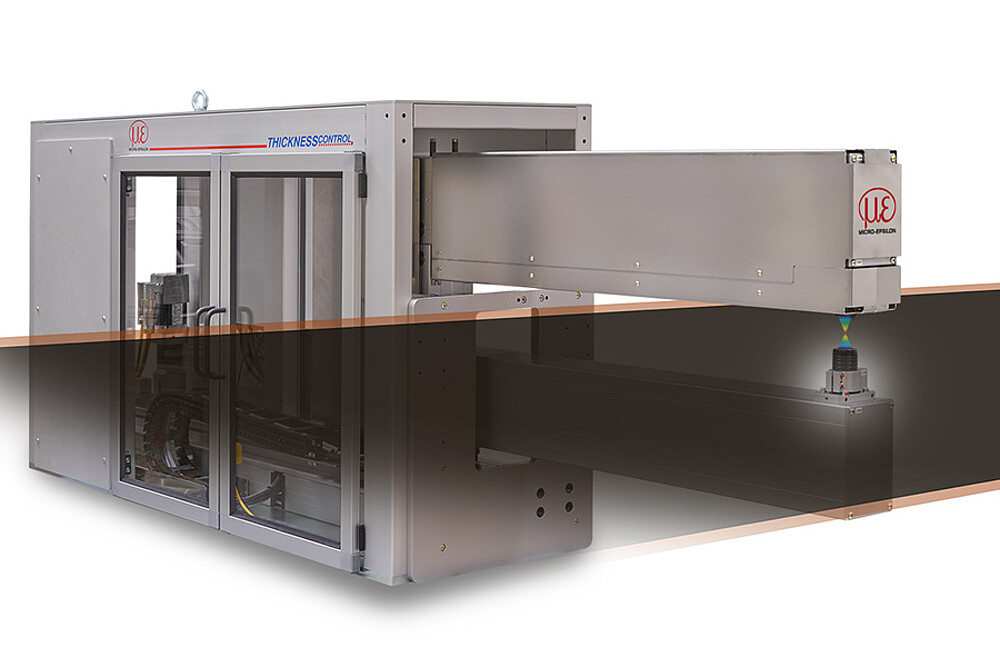

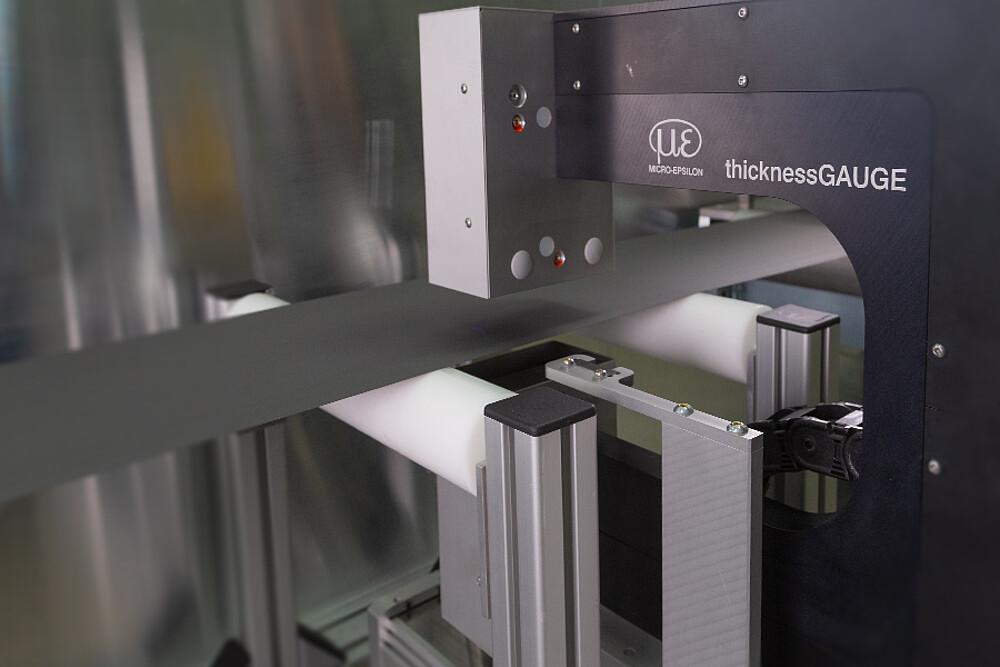

Inline systems for measuring the thickness of battery films

thicknessGAUGE sensor systems are used to measure the thickness of strip materials in-line. Several models with different sensor types, measuring ranges and measuring widths are available for precise thickness measurement. The systems use two optical or electromagnetic distance sensors to measure the strip thickness of cell material, films and coatings with micrometers.