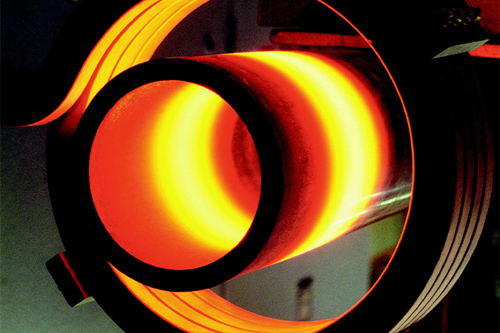

Kovovýroba a obrábění

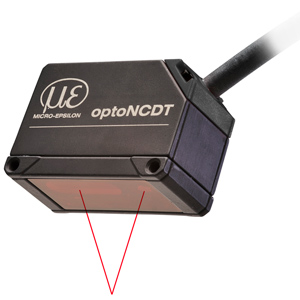

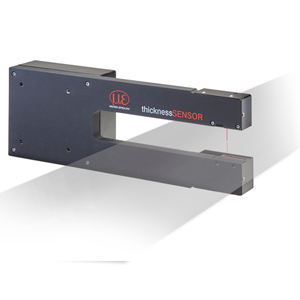

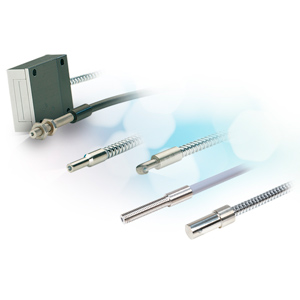

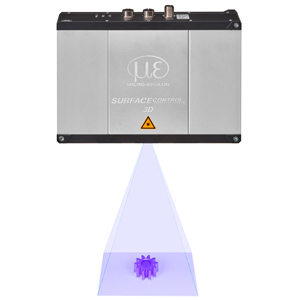

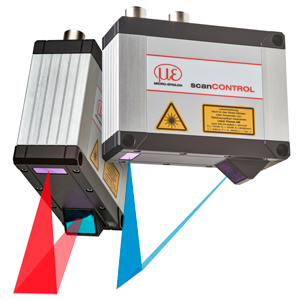

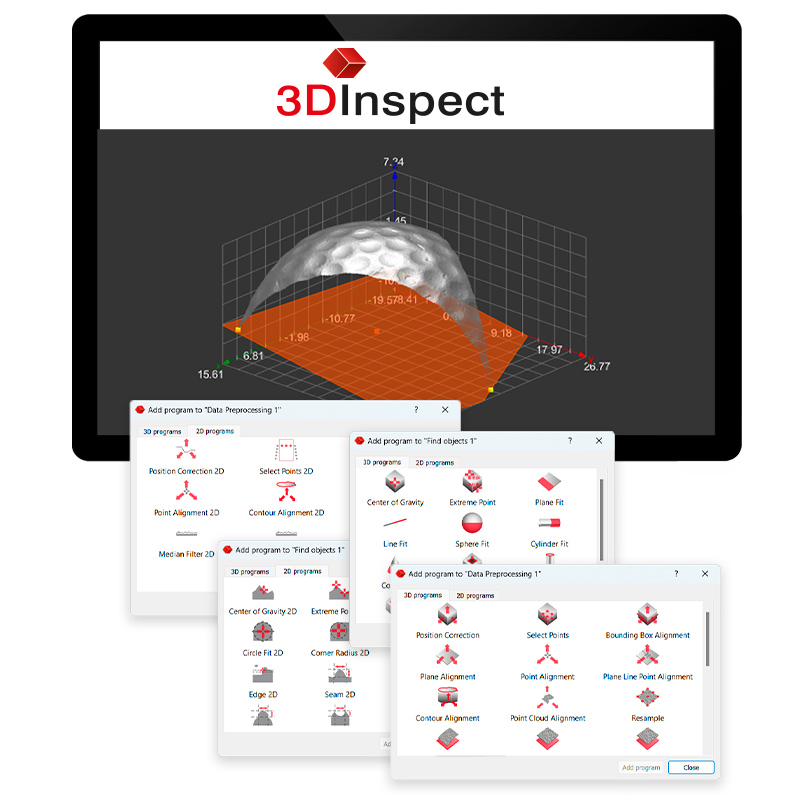

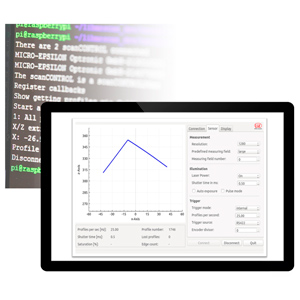

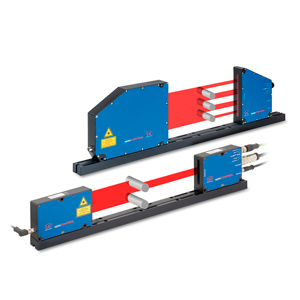

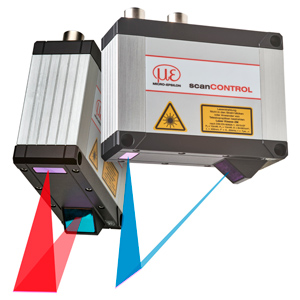

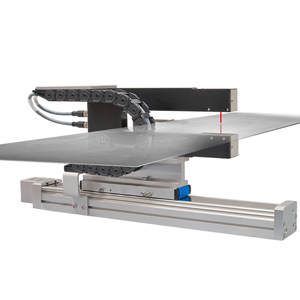

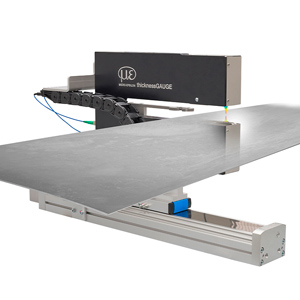

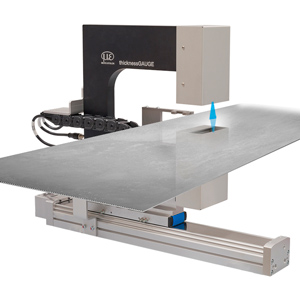

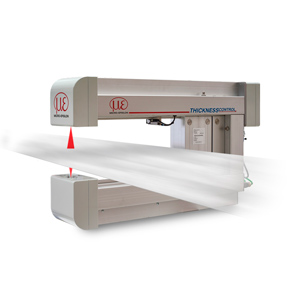

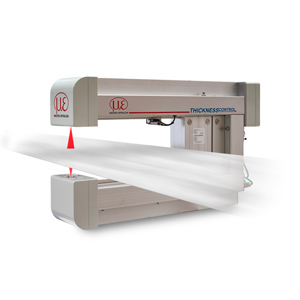

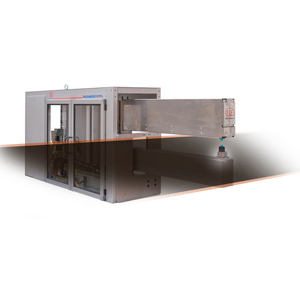

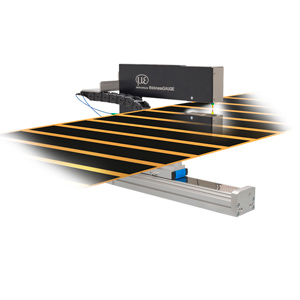

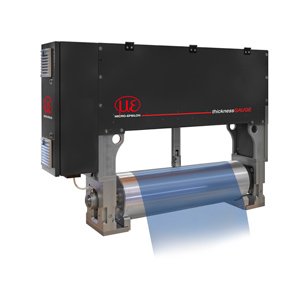

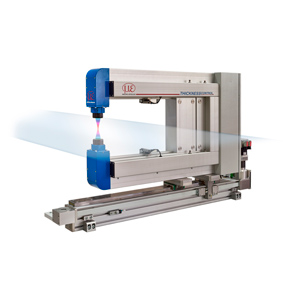

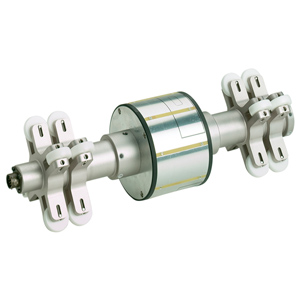

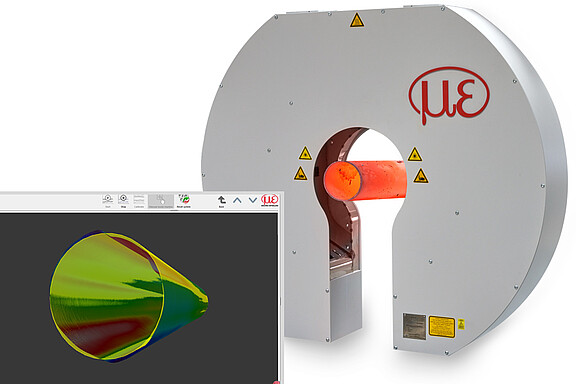

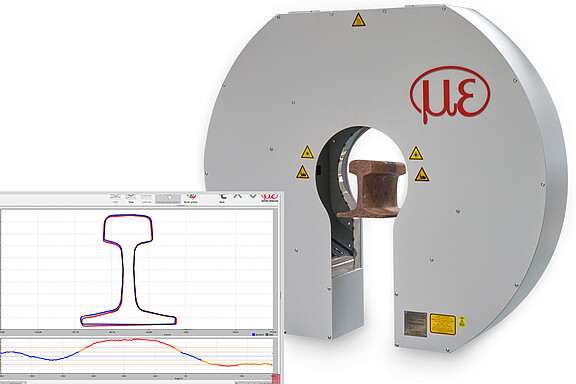

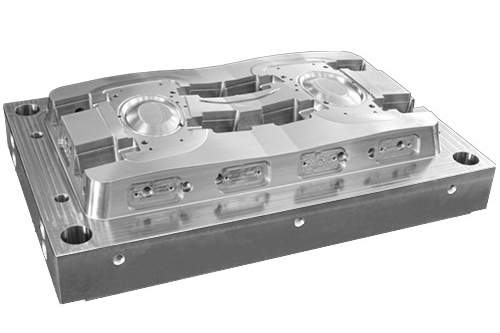

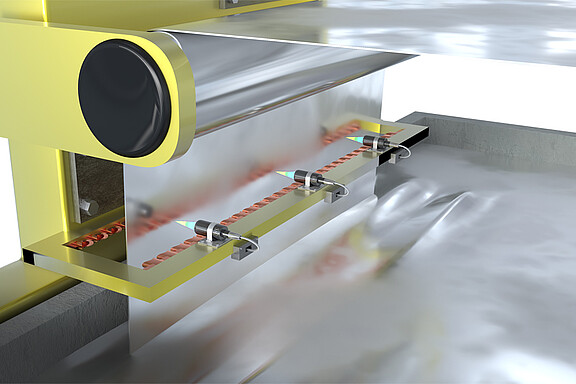

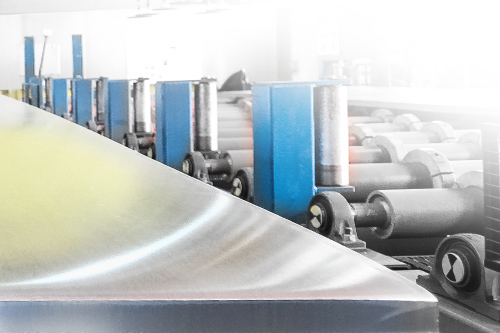

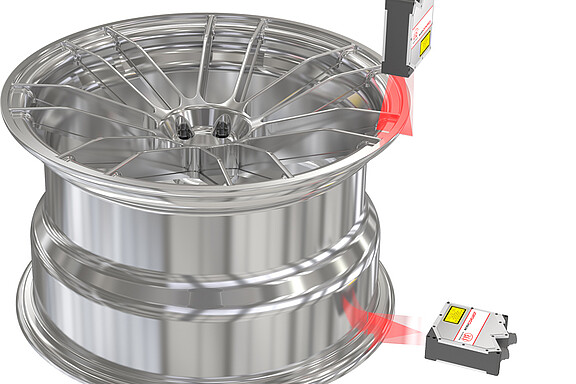

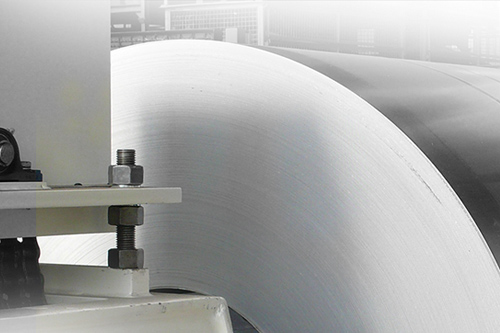

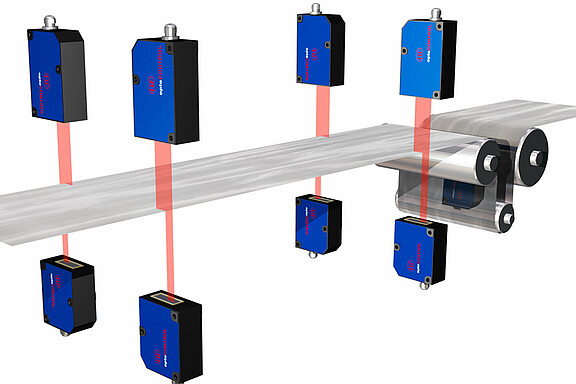

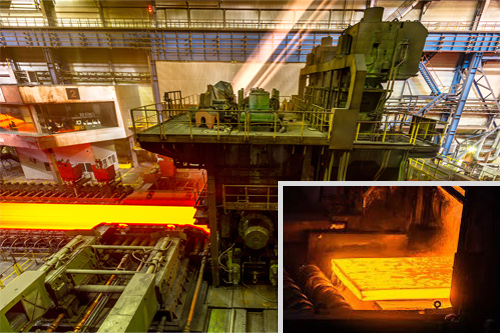

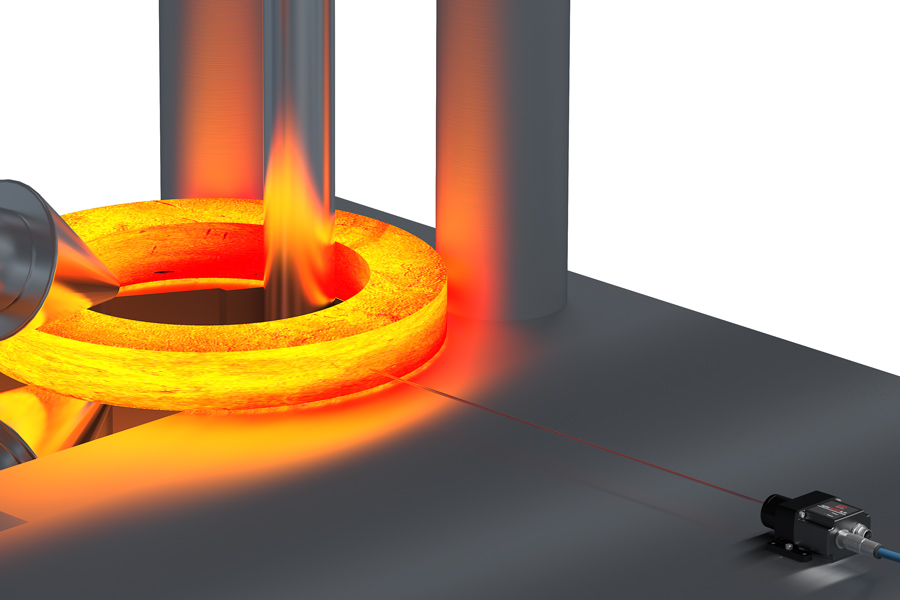

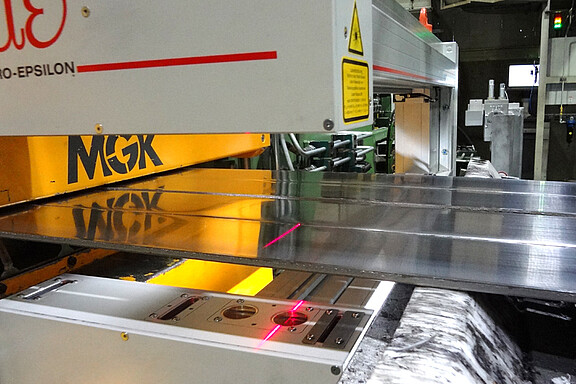

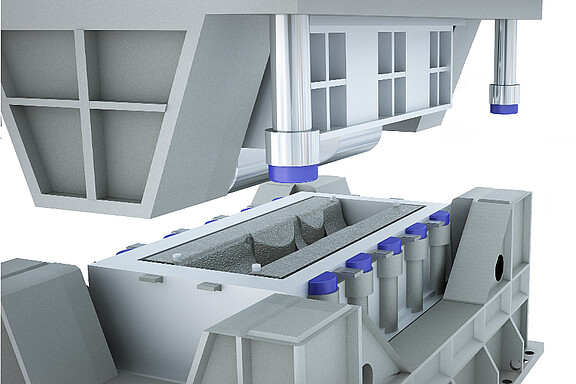

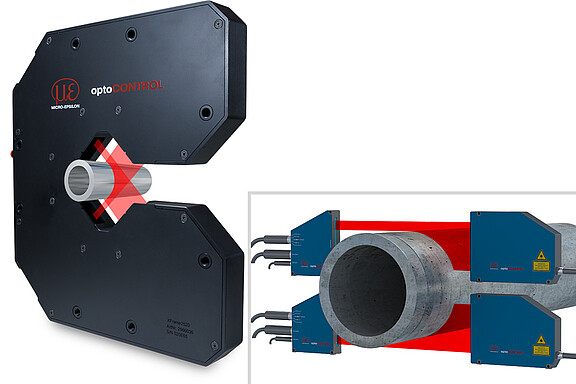

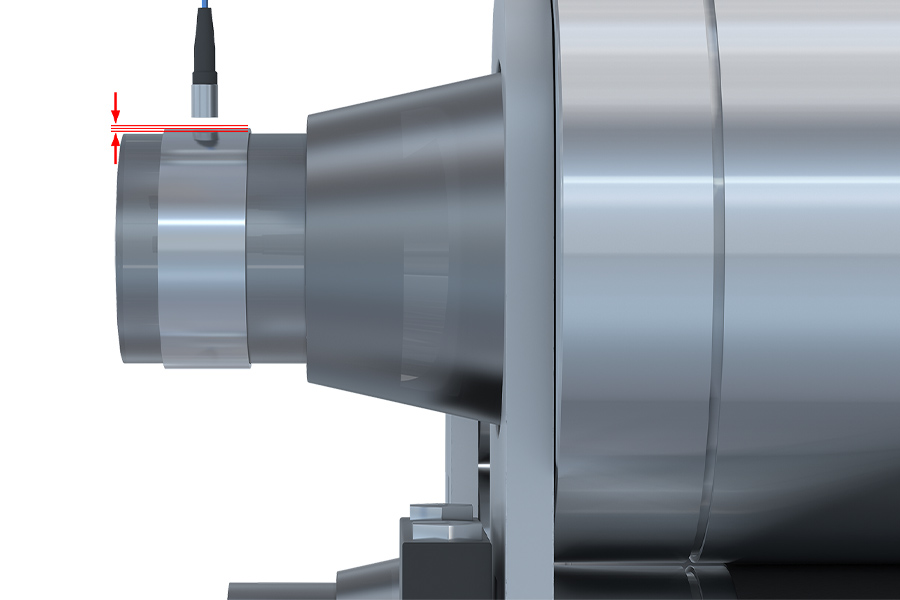

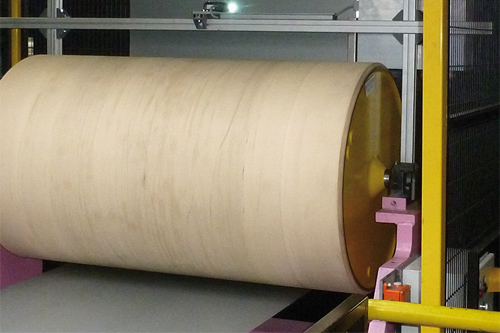

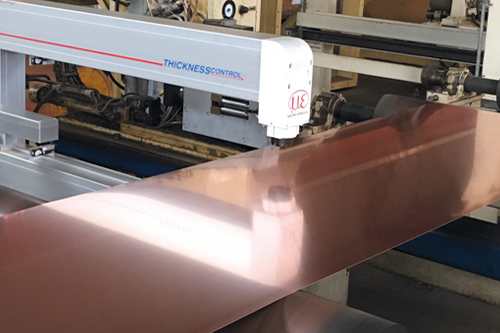

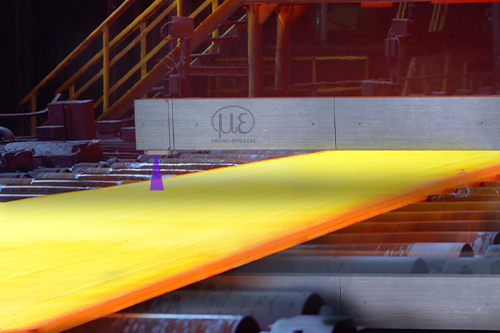

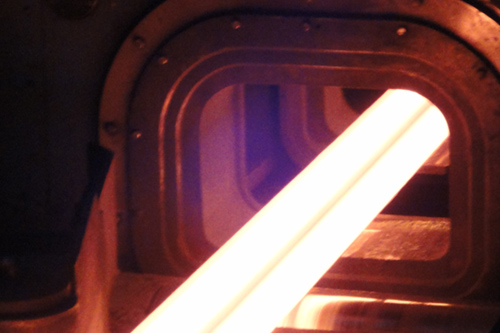

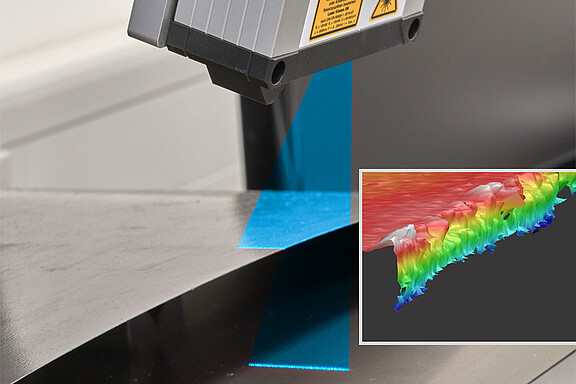

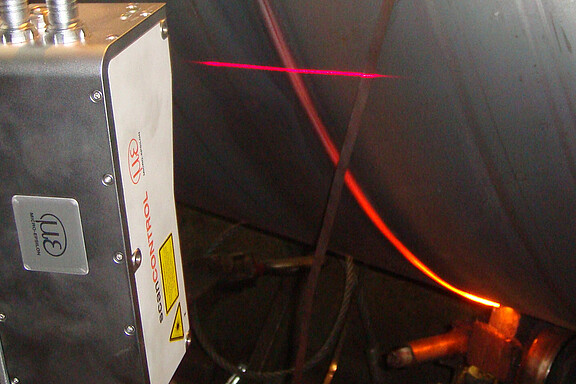

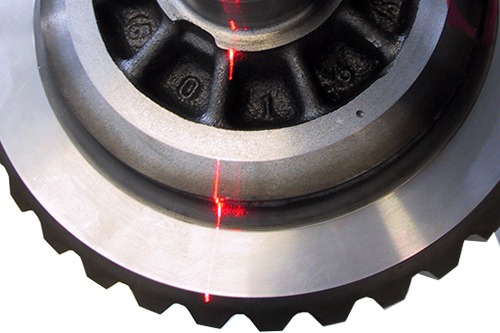

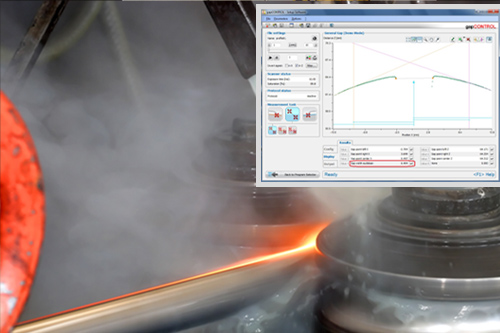

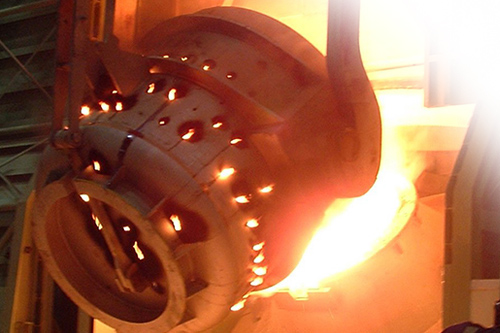

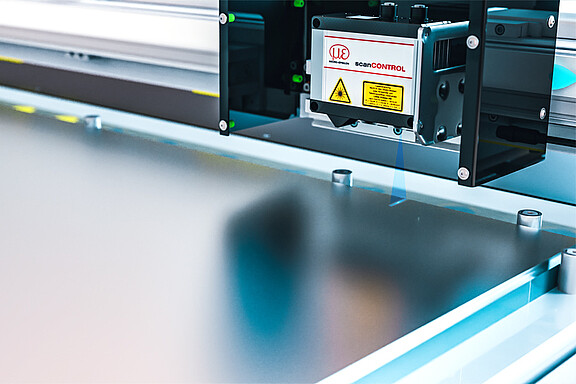

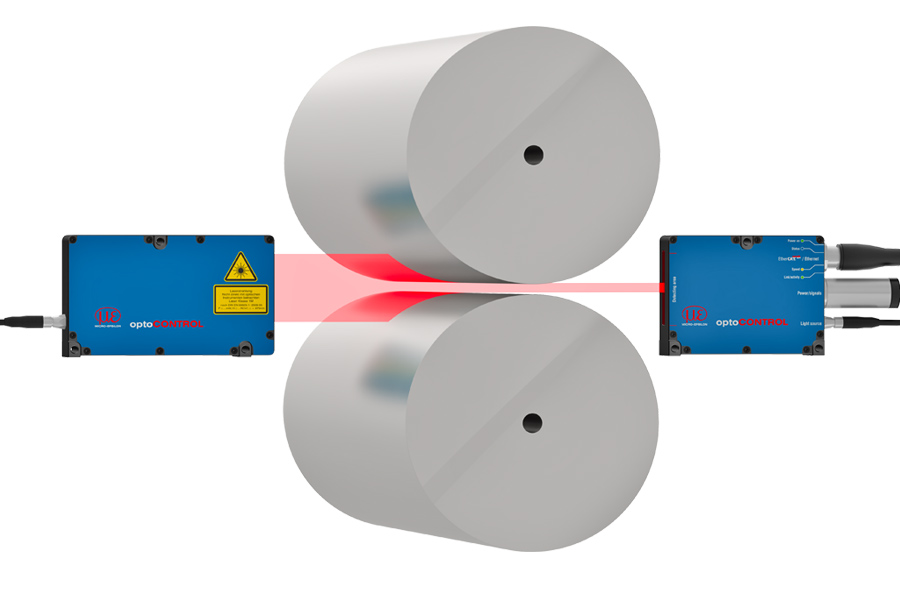

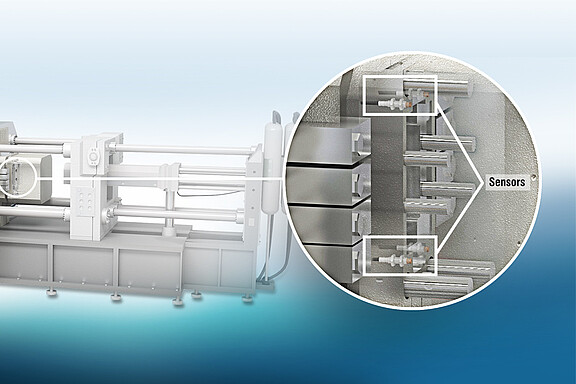

Inteligentní snímače jsou vyžadovány při výrobě, zpracování, dopravě a skladování kovových materiálů. Snímače umožňují efektivní a bezpečnou výrobu a později bezporuchové zpracování. Micro-Epsilon má odborné znalosti a know-how v široké škále aplikací: při umístění jeřábů, dílů a materiálů strojů při sledování tloušťky kovových pásů a desek na profilové měření lisovaných výlisků.